Solutions for Distilleries

Distilleries face unique challenges—from explosion protection and aroma integrity to sustainability and by-product recovery. Pentair delivers tailored technologies that help distillers operate safely, efficiently, and profitably, while meeting strict regulatory and environmental standards.

Engineered for Distillery Demands

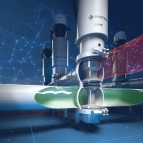

Pentair’s solutions are designed to meet the specific needs of distillery environments, including:

- Hygienic Valve Technology

- Seals that prevent aroma carry-over.

- Explosion-proof options for ATEX Zone 1.

- Custom valve configurations for high-proof alcohol handling.

- CO₂ Recovery & Ethanol Recovery

- CO₂ Recovery: Capture and reuse CO₂ in food-grade quality or better.

- EtOH Recovery: Recover ethanol efficiently to reduce waste and increase yield.

- CO₂ Scrub Solutions: Improve purity and create new revenue streams.

Related applications

Pentair provides reliable and high-performing CO₂ extraction and generation solutions for soft drink bottlers, ensuring a consistent supply of purified, food-grade CO₂.

Benefit from our extensive range of stainless steel hygienic and aseptic valves, complete manifolds, and prefabricated units.

CO2 Recovery for Beverage Producers

Comprehensive CO₂ recovery solutions, enabling efficient capture and reuse of CO₂ from fermentation sources or natural springs. This approach helps reduce costs, control CO₂ purity, and minimize dependence on external suppliers.

Microfiltration of Gases, Liquid & Steam

Pentair Haffmans CPM Microfiltration ensures that your gases, liquids, and steam are free of particles and oil to improve the quality of your process media.